Fertigation is the application of fertilizer together with the irrigation water. The most common form of fertigation in Kenya is via drip irrigation. Fertigation provides precise nutrition, application flexibility, minimized loses & environmental protection.

The benefits of drip fertigation to plants are that nutrients are applied directly into the active root zone with water, there is a uniform distribution of nutrients both in the root zone and in the field, the nutrients are already dissolved and ready for uptake by the roots and the plants enjoy a continuous even uptake, with no temporary deficiencies or excesses. Plants can only take nutrients up form wet soil – so applying the fertilizer with water improves uptake and reduces losses. There is less soil compaction and better aeration in the root zone.

The benefits of drip fertigation for the grower include improved efficiencies, higher yields, flower and fruit sizes. Continuous feeding of small amounts of fertilizer reduces the risks of fertilizer loses through leaching or run off reducing the environmental impact. Labor /water / fertilizer and power costs are lower. Weed pressure is reduced – as water is applied only around the crop’s root zone and paths remain dry.

Fertigation has a higher application flexibility and the amount of water and fertilizer applied can be quickly changed according to the plant size, growth rate, weather and soil type. Leaves do not get wet so there is a lower disease pressure. Water does not bounce off the soil onto the crop – meaning cleaner leaves, flowers and fruit and less chance of microbial contamination of vegetables.

Nutrients can be applied precisely, evenly and in very small amounts – this is especially important for micronutrients that are essential for good yields and plant health but can quickly become toxic. Nutrients are applied in small amounts and with water so there is less chance of salinity damage to the roots.

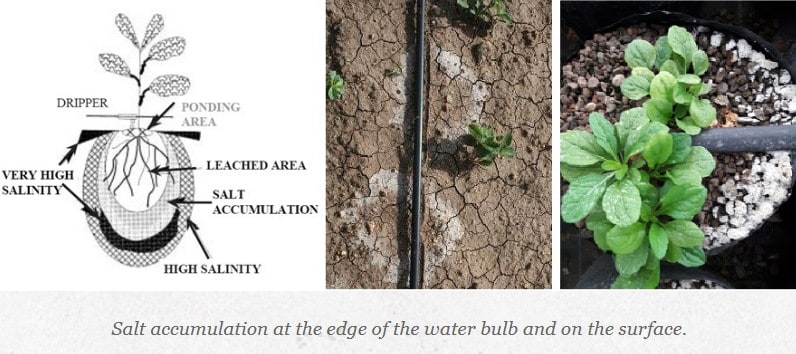

Fertigation allows the grower to use marginal quality water. Alkaline water can be acidified. Calcium and Magnesium can be added to reduce the toxic effects of sodium. Higher Electrical Conductivity (EC) water can be used because 1) there is less evaporation and 2) excess salts can be leached to the edge of the drip zone.

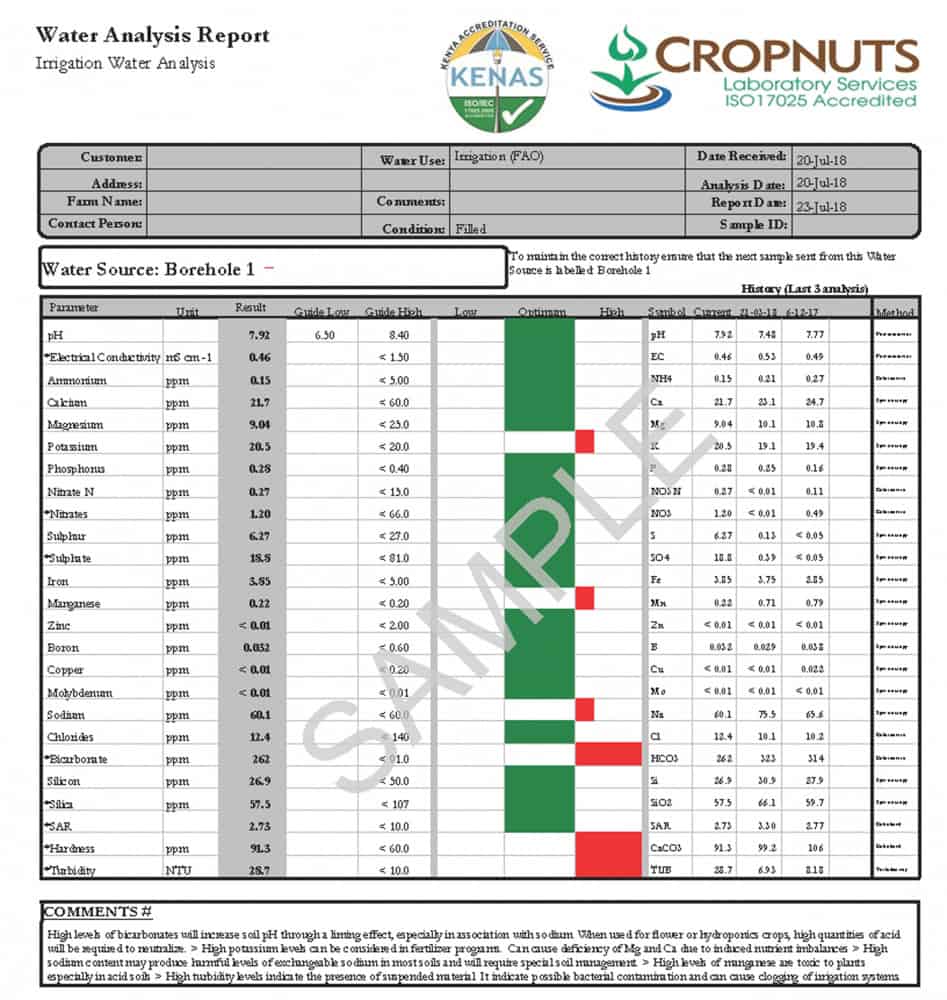

To design a suitable irrigation system the grower needs to know the quality and quantity of the available water, the area to be irrigated, the soil type and the crop water requirements. A proper irrigation analysis will identify how to treat the water (filtration, disinfection, oxidation) and what nutrients and water amendments need to be added.

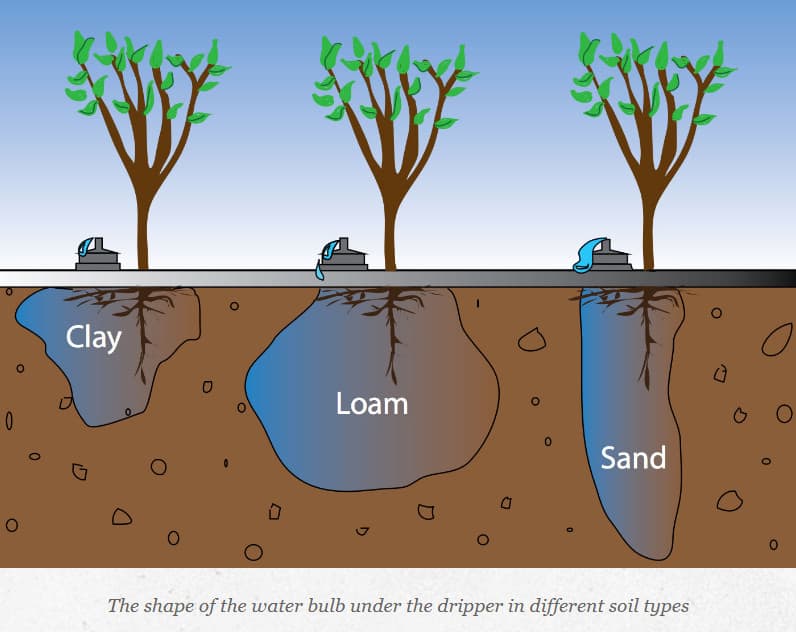

To achieve good results, drip systems should be designed according to soil types. The area wetted by the dripper (known as the water bulb) varies in shape according to the soil type. In porous sandy soils with a high infiltration and low water retention the bulb is long and narrow, and there is more risk of leaching.

Drippers should be closer together and the water applied in small amounts more often. Fertigation units should be able to apply the higher flow rates and the smaller doses that are required. In heavier clay soils with slower infiltration and higher water retention – the drippers can be further apart (less drippers / lower flow rate) and the water applied in large doses less often.

Once installed drip fertigation requires very good management to maximize the benefits. Proper testing and treatment of the water will reduce dripper blockages and improve fertigation efficiencies.

A high turbidity or Total Suspended Solids indicates a need for filtration to prevent physical blocking of dripper by solids. High algal or bacterial counts, iron, manganese or hydrogen sulphide will cause dripper blockage by organic slimes. A high hardness, Calcium, Magnesium, Phosphates, Sulphates or Bicarbonates will cause dripper blockage by inorganic solids.

If properly designed and managed, drip fertigation allows for a better salinity management and lower salt content of the soil in the root zone. Salts move with water and can accumulate at the edge of the water bulb due to water movement and on the soil surface due to evaporation. Dripper spacing, emission rate and length of irrigation cycle can all be varied to flush the excess salts away out of the root zone.

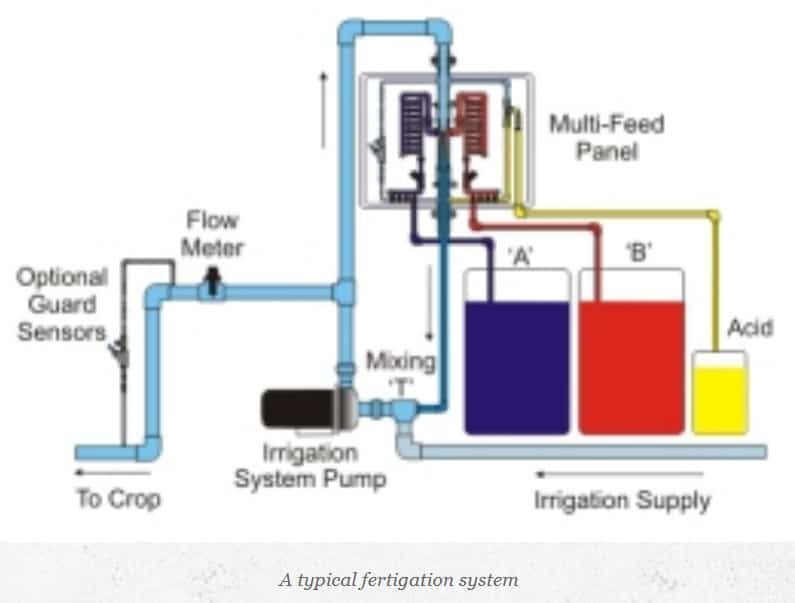

In fertigation, knowing the exact amounts of fertilizers that need to be applied is not enough. For successful mixing of fertilizers – the fertilizers must be fully soluble and of high quality with few inclusions. Factors to consider when preparing the stock solutions include, types of fertilizers to be used, fertilizer compatibility, fertilizer solubility, the number of stock tanks, the injection ratio, and the interaction of fertilizers with water (eg endothermic reaction, effect on EC and pH). A typical fertigation system may consist of Tank A and Tank B and an Acid Tank.

In general calcium / magnesium & potassium nitrates and iron chelates are mixed in Tank A and phosphates, magnesium and potassium sulphates and the other micronutrients are mixed in Tank B to avoid precipitation of Calcium Sulphate (Gypsum) or Calcium Phosphate, which block drippers.

Calcium and Magnesium can react with carbonates and bicarbonates -forming insoluble lime, this requires acidification of the water. Growers should perform their own bucket solubility tests of individual fertilizers to confirm maximum solubility look for impurities. Growers should also mix the fertilizers and observe any precipitation incompatibility.

Many problems are caused by mixing stock solutions that are too dilute for the injection rates (low EC / high pH, weak crops), or too concentrated (precipitation, drip blockages, nutrient loss inside the system). The nutrients present in the irrigation water should be considered to balance the recipe. The contribution of the nitrates or phosphates delivered by the amount of acid required to neutralize the alkalinity of the water must also be taken into account.

A good fertigation program is based on proper water management considering the plant water requirements, the soil type, and the irrigation equipment. The plants’ water requirement depends on plant type, stage of plant and climatic conditions (temperature, wind, radiation ambient humidity). The amount and the timing are both crucial to maximize plant health, growth and yields.

To know more about fertigation, to test your irrigation water or soil type, or for help planning your fertigation program please contact us at support@cropnuts.com.

Till next time,

Kindest regards,

Ruth

About Ruth

Ruth Vaughan is the Technical Director at Crop Nutrition Laboratory Services Ltd. (CROPNUTS). Ruth is also a contributing author to Kenya’s leading horticulture magazines such as the HortFresh Journal, HortiNews and Floriculture. Ruth is a great believer in soil health, organic matter, biochar and carbon sequestration as a way to alleviate climate change and increase food security. Loves visiting farmers and seeing all the different farming methods

Order our services and get to know how to improve your soil for better yeilds.