Top dressing fertilizer for maize works best when the timing is key; ie. when it is applied at the correct crop growth stage and at the recommended rate.

This is why: For maize, Urea application timing depends on an understanding of the key growth stages. As many crops reach top dressing timing, we look at the main requirements of the crop.

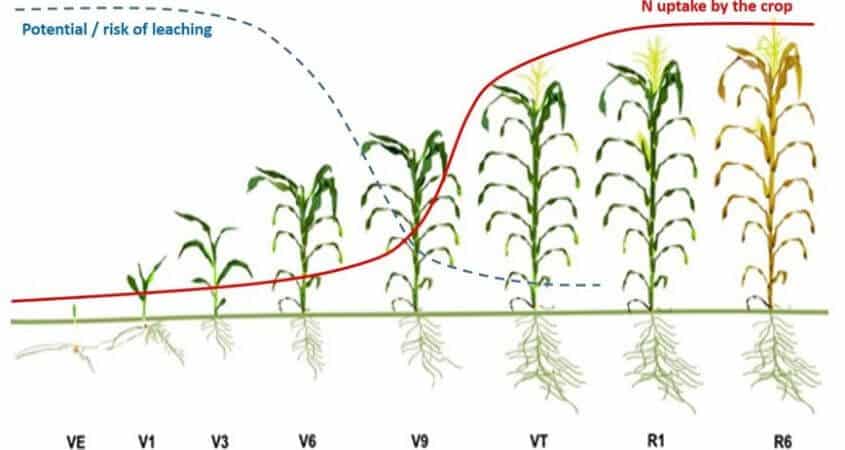

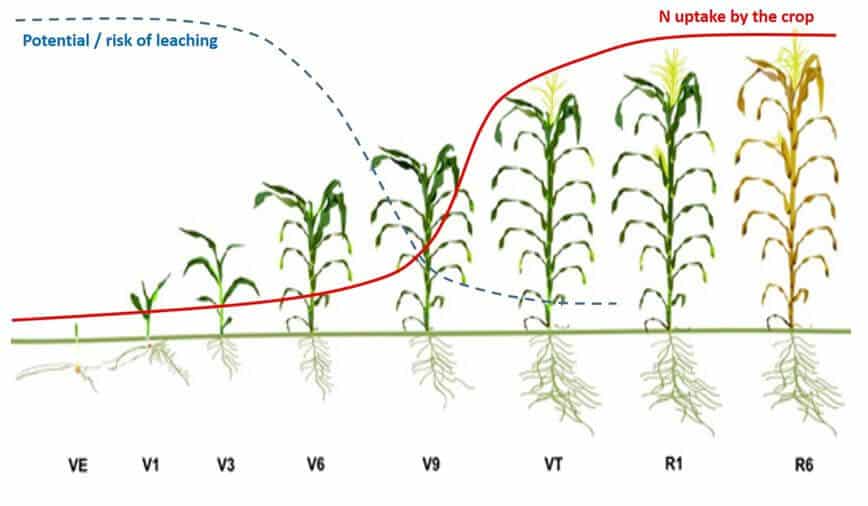

Nitrogen applied at the 3-4 leaf stage with a broadcaster leaves nitrogen vulnerable to leaching when the crop does not require it.

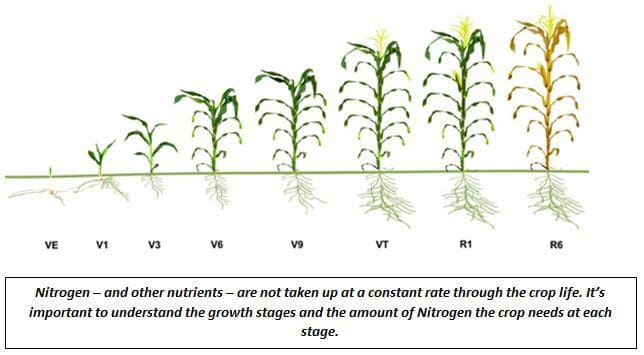

Nitrogen – and other nutrients – are not taken up at a constant rate through the crop life. Therefore, the table below summarises the important growth stages and the amount of nitrogen in particular that the crop takes up at each stage.

| What is happening in the crop? | Kg of N taken up | |

| V1 | Crop emerging | |

| V3 stage | 3 leaf stage, crop established | 12 kg/ha N |

| V6 | Growing point and tassle at ground level | 25 kg/ha N |

| V8-V10 | Rapid top growth period | 80 kg/ha N |

| V12 | The number of rows of kernels determined. Rapid nutrient uptake | 100 kg/ha N |

| R1 | 140 kg/ha N | |

| R3 | Little further N uptake | 250 kg/ha N |

| R6 | Physiologically mature |

Applying at 3-4 leaf stage leaves probably a 4-6 week gap before the crop is really taking up the fertilizer. Even slow-release top dressing fertilizer for maize do not overcome this in trials that I have been involved with. This is especially true in seasons with well over 600mm of rainfall like we are experiencing now.

Nitrogen takes time to get into the crop. In most cases, the optimum is around the 8-10 leaf stage for top dressing fertilizer for maize. There were certainly a number of crops in the North Rift that I looked at last week that were getting short of nitrogen at this stage where topdressing was delayed.

Do not forget, leaching has been significant this year with the high rainfall. This is why leaf tests (or leaf nutrient analysis) are an important tool to take a snapshot of what is happening inside the plant. They will also highlight other nutrients and I use them to guide:

When we have decided how much top dressing fertilizer for maize to apply, consider splitting the application.

To see the logic of delaying nitrogen top dressing and look at the greatest risk of leaching in the early stages, we plotted the N uptake onto a growth stage chart.

In recent years there has been a trend among maize growers to apply Calcium Ammonium Nitrate (CAN) fertilizer to their crops in preference to Urea. The lower volatilization risk in dry soils and the perceived neutral effect on soil acidity has encouraged the trend, along with the subsidized price through the National Cereals Produce Board (NCPB).

But how accurate are these claims, and what is the best value approach for your crop? Calcium Ammonium Nitrate (CAN) contains 28% nitrogen typically and is rapidly and efficiently taken up by plants. The Nitrogen content is far lower than Urea however which contains 46% nitrogen, so the actual cost per Kg of Nitrogen is more expensive (calculations done with 2017 fertilizer bag prices):

We can see here that the Nitrogen in Calcium Ammonium Nitrate (CAN) costs 65% more than Urea because it is less concentrated. So even if some N is lost after applying Urea, it is still far less expensive than CAN. Applied in the right conditions to moist soils, losses are very small. In most soils the acidifying effect of Urea is minimal, and the Calcium in CAN is not in a form that is particularly available.

Maize can easily achieve 9 tons/ha (40 bags per acre) with the right agronomy and adequate moisture, but it does require adequate nutrition to achieve this. The amount of fertilizer required is best calculated by multiplying the target yield in tons per hectare, by 20-25 Kg. For a 30 bag per acre crop this is 160 Kg of nitrogen.

Timing is final part of getting fertilizer right; DAP or a compound fertiliser at planting forms a good base for crop emergence, with the balance applied as urea as a topdressing. Soil Mineral Nitrogen testing can help too, by accounting for residual nitrogen in the soil profile.

And finally, top yields require accurate application. This can be discussed in detail with your CropNuts agronomy contact for independent agronomic advice.

https://cropnuts.com/service/crop-consulting/

When discussing types of fertilizer for Nitrogen topdressing you can always be sure of lots of debate about the merits of Urea vs Ammonium sources such as Calcium Ammonium Nitrate (CAN) .

Urea remains the least expensive form of Nitrogen at around 80 – 90 Kes per kilo of N compared to around 115 – 135 kes in CAN (depends on the volatility of fertilizer bag prices). But what are the likely volatilization losses, and is it possible to go some way predicting this?

Firstly, there is actually surprisingly more data out there than you might imagine given the intensity of the Urea vs CAN debate. The problem is, very little of this work has been carried out in Africa, in our conditions. Should we be worried?

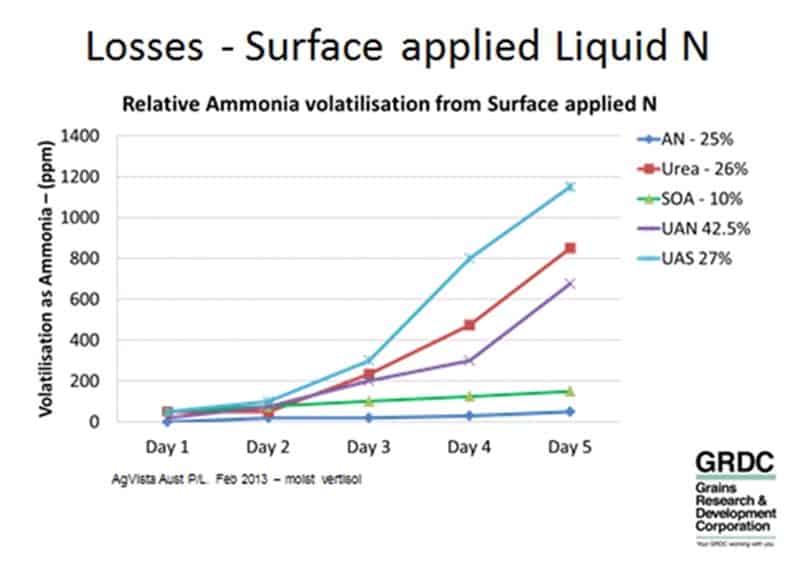

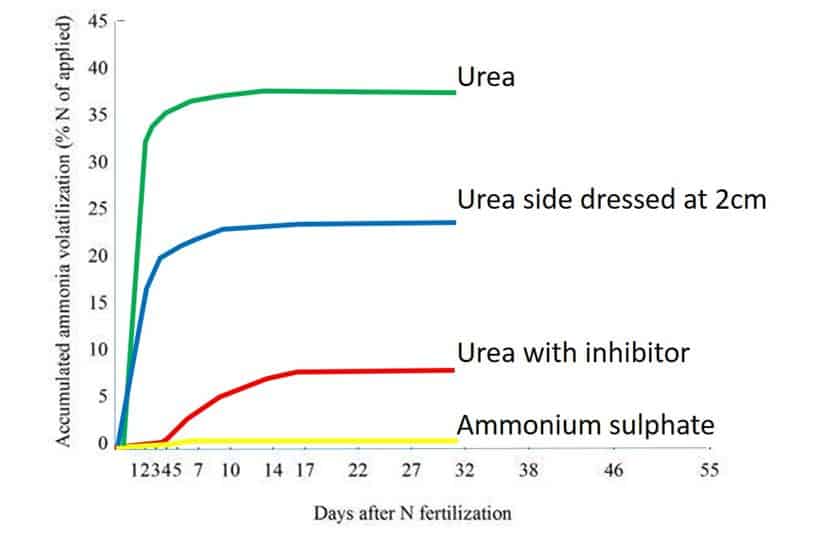

The losses of ammonia measured in a GRDC trial in Australia in liquid fertilizer is summarized in the graph and shows what can happen over 5 days of unfavourable conditions – losses topped out at nearly 30% of the total N applied in the Urea. Ammonium Sulphate lost only around 5% of its nitrogen.

Some very extensive work was carried out in the UK by ADAS in the 1980s which concluded that Urea was only a few percent less efficient that Ammonium Nitrate in most conditions.

More recent work suggests that while urease inhibitors and controlled release fertilisers do work effectively, the overriding views of independent researchers that I speak to is that losses from untreated urea are rarely large enough to make a coating / inhibitor worthwhile.

Looking at recent GRDC work in Australia the consensus is that a maximum of 20% of applied N is lost from Urea, and usually far less (link at the bottom).

That said, in the real world there are often practical reasons for using them as we cannot always spread large acreages in perfect conditions, and if the weather forecast is wrong having some protection on the urea to reduce losses it very desirable.

Ultimately it comes down to an individual farmer’s perception of risk, and farmers should remember that if you happen to be on alkaline soils they behave much differently, as research from Canada highlights.

So in summary, don’t be afraid of applying urea fertilizer to maize but if you have large acreages to spread and conditions go against you, consider a urease inhibitor or controlled release product. Just don’t expect big improvements in most conditions.

Pros

+ Fast and accurate

+ Minimises wheelings and therefore compaction

Cons

– Needs to be tray tested to get the spread pattern right

– Requires good quality fertiliser to get the spread

– Prills or granules can land in the leaf whorl and burn the plant

– Three point linkage on smaller tractors may not be sufficient to get the spreader to the correct height above the crop.

Pros

+ Accurate – no issue with spread pattern

+ No fertiliser prills/granules falling into leaf whorls and causing damage

Cons

-More wheelings and compaction

-Slow work rate

Pros

+ Far less risk of volatilisation with urea products

+ Accurate, and you only have to do in between every other row

Cons

-Slow work rate

-Soil disturbance, especially in notill situations. Also disrupts the herbicide layer.

Pros

+ Fast and no leaching losses

+ Can combine with a fungicide in many cases

+ Often see yield responses above even a high topdressing dose. Very useful if topdressing has leached

Cons

– Prone to scorch and leaf damage

-Requires high clearance sprayer

-Requires some basic equipment to mix the product

Whatever you do, always try to apply a double and a nil (half rate) rate strip to understand the response that the crop is giving you.

I reckon that our broadacre clients typically spend between Ksh. 4,000 (USD 40) and Ksh. 11,000 (USD 110) per hectare on topdressing fertilizer for maize, wheat or barley. When you consider the value of the fertilizer that we spread each single season, it is often greater than the value of the machine that we use to apply it.

On top of this, there are so many different grades of the fertilizers available to do the same job; different prill sizes and qualities, nitrogen and sulphur blends for example, that can allow savings in time and money – if they can be spread accurately.

Choosing the correct fertilizer spreader can open up possibilities for the material you spread, and importantly can help you get the job done quickly and efficiently when the application window is right…

This will normally depend on tramline width, but a high quality material such as Yara’s Amidas or ETG’s Kynoplus will happily spread to over 40 metres. Lower quality Ammonium Sulphate and Urea on the other hand is a much less expensive way of buying sulphur, but will require two passes and the AS will struggle to spread even 12 metres.

An important consideration for larger farms, as the option of buying in bulk 1 ton bags will soon become a reality.

The smaller the fields and the more short work you have, the more this will pay you back in reducing overlaps and also minimizing lodging on the headlands. Everyone talks about the pros and cons of Urea vs Calcium Ammonium Nitrate (CAN) fertilizers and volatilization etc. In reality many farmers can improve their efficiency far more by spreading their fertilizer correctly!!! Accurate section control also avoids under-application on the headlands; the largest part of the field.

On-the-move calibration allows lower quality materials to be used, because even when the density changes the spreader adjusts and still applies the same amount. The real top-end machines have torque-sensing on the disc shafts that detect the amount of fertilizer on the disc and adjusts the position of the fertilizer falling onto the disc to maintain the spread pattern.

Bredal have a very good forced metering system using a small belt to deliver the fertilizer right onto the discs. Great for slightly variable quality fertilizer where the odd lump or damp bag needs some help to get through the machine evenly.

Plug-and-go into the tractor controls is a must for section control and allows variable rate application plans to be fed into the machine – something that the very best performers are already doing.

Often forgotten, but making a machine easy to fill can save hours when there is a short window to apply the fertiliser and you are re-filling every 20 minutes. High fill spreaders are great with tractor loaders and handlers, but it is amazing how often you see cracks in the frame where operators drop them right onto the ground to get the hopper low enough.

An important consideration for topdressing tall crops such as Sunflowers!

Easy to couple up to the tractor with no PTO, and more precise disc speed and spread pattern over hilly terrain.

Top Tip – our trials are continually highlighting the need to feed wheat and barley early with a small dose of nitrogen, at the 2-3 leaf stage. Unlike much of the advice taken from Northern Europe for example we plant into warm soils with 12 hours of daylight, and tiller numbers are laid down early. For our agronomy clients this has implications for fertilizer strategies, and topdressing capabilities may require a rethink on some farms.

Till next time,

David

David Jones is the former Broad Acre Specialist at Crop Nutrition Laboratory Services Ltd. (CROPNUTS). David has a keen interest in soils and no till farming systems where he has undertaken work looking into weed levels and changes in soil structure, and has extensive experience in field trials and in the development of precision farming techniques. In his spare time he enjoys playing rugby.

Order our services and get to know how to improve your soil for better yeilds.